Magma Build Studios Capabilities: Metal Fabrication Techniques

Metal fabrication is a multifaceted craft that combines technical expertise, creativity, and a deep understanding of materials. From cutting-edge 3D printing to ancient casting techniques, the world of metal fabrication offers a rich tapestry of possibilities.

Whether you seek precision, strength, functionality, or artistic expression, Magma Build Studios has the custom metal fabrication talent to make it a reality. Our team transforms raw metal into extraordinary creations through a variety of metal fabrication techniques, like those outlined below. Our process allows us to balance the artistry and innovation of metal fabrication with the practical needs of your project.

Common Metal Fabrication Techniques Used by Magma Build Studios

Custom metal fabrication encompasses a wide range of techniques, each with its own unique characteristics and applications. In this article, we will explore several popular metal fabrication techniques, shedding light on their capabilities and the magic they bring to the world of architecture and design.

Welding: Fusing Metal for Structural Integrity

Welding is a widely utilized metal fabrication technique that involves permanently joining metal pieces by melting and fusing them together. This process typically employs intense heat and a filler material to create a strong bond. Welding techniques vary, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and arc welding, each suited for different materials and applications. Magma Build Studios has used welding for everything from constructing custom railings and room partitions to crafting unique furniture and decorative elements.

Fabricating: Assembling and Joining Metal Components

Fabricating encompasses the process of taking individual metal components and joining them together, either mechanically or through welding. It involves cutting, bending, and shaping metal pieces to fit a specific design or structure. Fabrication techniques allow for the creation of customized products, including furniture, architectural elements, and decorative lighting.

Sculpture: Shaping Metal into Artistic Expressions

Sculpture involves the artistic shaping and manipulation of metal to create expressive and visually captivating pieces. Sculptors employ various metal fabrication techniques, such as welding, cutting, bending, and casting, to transform raw metal into intricate works of art. Metal sculptures can range from abstract forms to lifelike representations, showcasing the boundless creativity that can be achieved with metal as a medium.

Browse our art fabrication gallery to see examples of our metal sculptures and other projects.

3D Printing: Revolutionizing Metal Fabrication with Precision

3D printing has emerged as a groundbreaking technique in metal fabrication. This innovative method utilizes computer-aided design (CAD) models to create three-dimensional objects layer by layer. With the advent of metal 3D printing technologies, intricate and complex metal components can now be produced with unparalleled precision. From refining models to scaling details, 3D printing opens up new possibilities for customizability, prototyping, and rapid production.

Casting: Molding Molten Metal into Shape

Casting is an ancient metal fabrication technique that remains widely used today. This process involves pouring molten metal into a mold, allowing it to solidify and take the desired shape. Casting techniques can vary, including investment casting, sand casting, and die casting, among others. Casting enables the creation of intricate and detailed metal components, making it an ideal choice for sculptural pieces and industrial parts. Casting also allows Magma Build Studios to cost-effectively mass produce metal components for large projects.

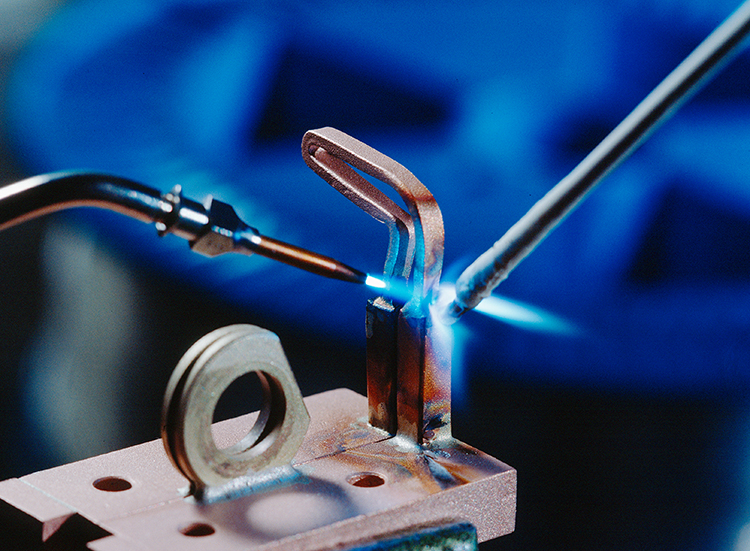

Soldering: Joining Metal with Heat and Filler Material

Soldering is a technique used to join metal pieces together using heat and a filler material called solder. This process creates a strong bond between the metals, primarily through the solder’s low melting point. Soldering is commonly utilized by Magma Build Studios for electrical and electronic applications including lighting, integrated speaker installation, incorporated security systems, and other mechanical components. It offers versatility and ease of use, allowing for precise connections and repairs.

Brazing: Achieving Strength through High-Temperature Bonding

Brazing is a metal fabrication technique similar to soldering but performed at higher temperatures. It involves joining metal components using a filler material with a higher melting point, typically a brass or silver alloy. Brazing creates robust and durable connections, making it suitable for applications that require strong joints, such as railings, sculptures, and partitions.

Forming and Shaping Sheet Metal: Craftsmanship in Thin Layers

Forming and shaping sheet metal is a technique that focuses on manipulating thin, flat sheets of metal into desired shapes and structures. Processes like bending, rolling, and stamping are used to achieve specific geometries and designs. Sheet metal fabrication finds application in architectural design when lightweight yet sturdy components are required.

Metal Fabrication by Magma Build Studios

From the graceful elegance of brass to the enduring strength of steel, Magma Build Studios has extensive experience in metal fabrication for a variety of applications and aesthetics. Our team of seasoned metal fabricators can transform your concept into a reality with precision and artistry. We have the expertise to handle projects of any magnitude or intricacy. Whether you require tailor-made decorative lighting, architectural elements, sculptures, or furnishings and decor, our commitment to meticulousness and our focus on delivering excellence guarantees outstanding outcomes.